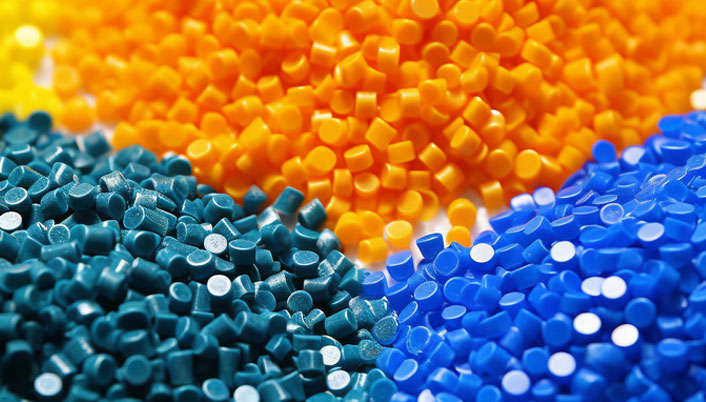

Polymer masterbatches have revolutionized polymer processing, offering multifaceted advantages across diverse industries. These concentrated mixtures, encapsulating additives or colorants within a carrier material, redefine manufacturing processes and elevate product quality. Delving deeper into their versatility and benefits unveils a spectrum of advantages:

Efficient Additive Integration:

Polymer masterbatches streamline the addition of additives, enabling pellet-to-pellet blending or direct extruder addition. Their use eliminates the complexities associated with handling minute powder amounts, rendering specialized dosing equipment unnecessary and ensuring precise and simplified addition processes.

Enhanced Product Consistency and Stability:

Employing additive masterbatches ensures superior dispersion, fostering uniformity and stability in product quality. Their efficient dispersion minimizes rejected parts due to inconsistencies, maintaining color integrity, and other critical properties essential for product quality.

Safe Handling of Hazardous Materials:

Encapsulation of additives within masterbatches mitigates the hazards linked to handling potentially dangerous materials. This encapsulation minimizes risks, reducing the need for extensive engineering controls and personal protective equipment, promoting a safer workplace environment.

Cleaner and Efficient Production:

Masterbatches devoid of loose powdered additives result in cleaner production environments, mitigating potential contamination risks. Reduced airborne pigments or additive spillages contribute to minimized cross-contamination, ensuring smoother transitions between varied products.

Extended Additive Stability and Shelf-Life:

Acting as protective shields, masterbatches safeguard additives against environmental degradation during storage. This preservation extends their shelf life, mitigating material loss due to degradation induced by factors like moisture, temperature, or UV exposure.

Seamless Integration of Antimicrobial Technology:

Polymer masterbatches facilitate the effortless integration of antimicrobial additives, offering versatile solutions across diverse applications. Their use streamlines the incorporation of these technologies, ensuring ease of implementation and effective antimicrobial performance in various polymer-based products.

Polymer masterbatches serve as indispensable tools, not only optimizing manufacturing efficiency but also enhancing the performance and quality of end products. With their versatility and array of benefits, they continue to redefine industry standards and innovations across numerous sectors.

-300x210.jpg)