Application areas of antimicrobial agents

Antimicrobial Coatings and Paints

What is an antimicrobial coating?

An antimicrobial coating is a type of surface treatment that contains antimicrobial agents, which are substances that inhibit the growth and spread of microorganisms such as bacteria, viruses, fungi, and other pathogens. These coatings are applied to various surfaces, including metals, plastics, textiles, glass, and ceramics, to create a protective barrier that can kill or prevent the growth of harmful microbes.

Mechanism of antimicrobial coatings

Antimicrobial coatings work by releasing antimicrobial agents onto the surface, creating an inhospitable environment for microorganisms. They can disrupt the cell walls of bacteria, interfere with their metabolic processes, or inhibit the replication of viruses. This helps to reduce the risk of cross-contamination and the spread of infections in environments where these coated surfaces are used.

What are the different types of antimicrobial coatings?

Types of antimicrobial coatings can be classified based on their material and form. In terms of material, they can be divided into organic and inorganic types. In terms of form, they can be categorized into powders, liquids, films, and sheets.

Material Classification:

a. Organic Antimicrobial Coatings: These coatings utilize organic compounds as antimicrobial agents, with common examples being triazine compounds, quaternary ammonium salts, and others.

b. Inorganic Antimicrobial Coatings: These coatings employ inorganic elements or compounds as antimicrobial agents, such as silver, copper, zinc metal ions, titanium dioxide, and more.

Form Classification:

a. Antimicrobial Powders: Antimicrobial agents are added in powder form to materials like coatings and plastics to create antimicrobial coatings.

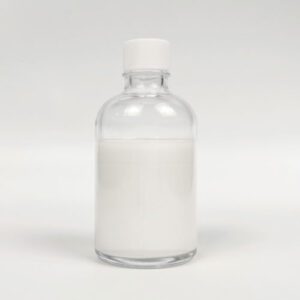

b. Antimicrobial Liquids: Antimicrobial agents are incorporated as liquid additives in various coatings, disinfectants, and cleaning solutions for surface treatment.

c. Antimicrobial Films: Antimicrobial agents are encapsulated within film materials, forming thin films with antimicrobial properties suitable for surface coating or composite materials.

d. Antimicrobial Sheets: Antimicrobial agents are directly added to plastics, rubbers, or other sheet materials, rendering the entire material with antimicrobial characteristics.

How long does antimicrobial coating last?

The longevity of antimicrobial coatings varies depending on the type of antimicrobial agent used, the application method, and the conditions in which the coating is used. Generally, antimicrobial coatings can provide protection for varying durations, ranging from several months to several years.

For traditional organic antimicrobial coatings, their effectiveness may last for a few months or even shorter periods. These coatings may require regular reapplication to maintain their antimicrobial properties.

In contrast, inorganic metal ion antimicrobial coatings, such as those infused with silver, copper, or zinc, tend to offer longer-lasting protection. These coatings can remain effective for one year or even several years, depending on the specific application and the amount of antimicrobial agent present.

Antimicrobial slurries for coatings and paints

Antimicrobial powder for coatings and paints

Antimicrobial masterbatch for films and sheets